Various Altec manufacturing and test facilities

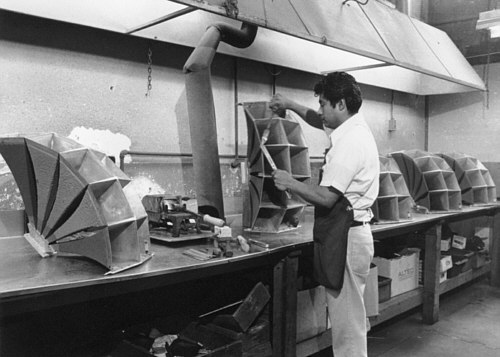

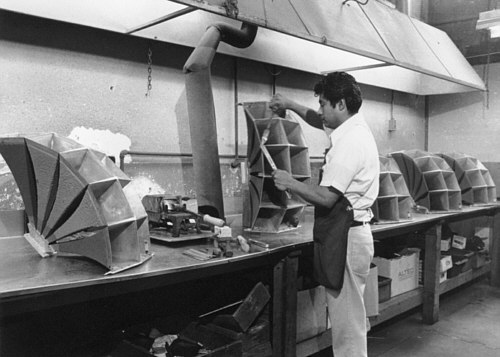

Photo 26 - Manufacturing multi-cell horns

Anaheim shop. Probably these cells have the spray-on damping and are not

tar-filled. The multicell solderers were the highest-paid craft anywhere in

the Altec plant - t.u.

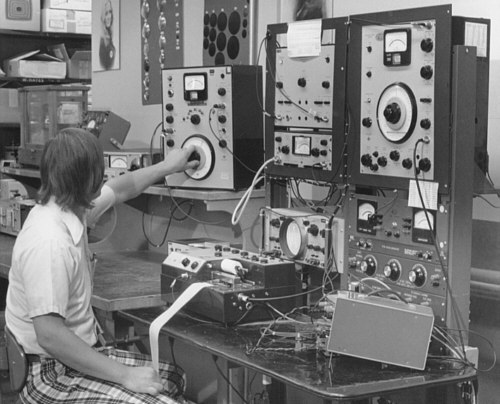

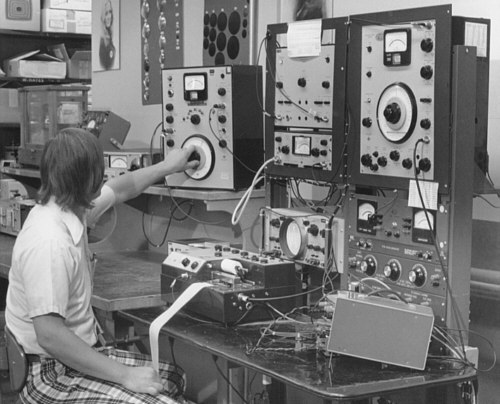

Photo 21

Microphone test area in Anaheim - t.u.

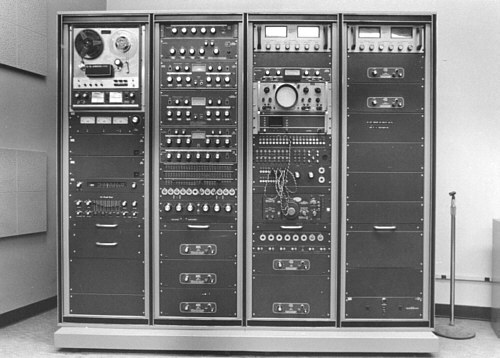

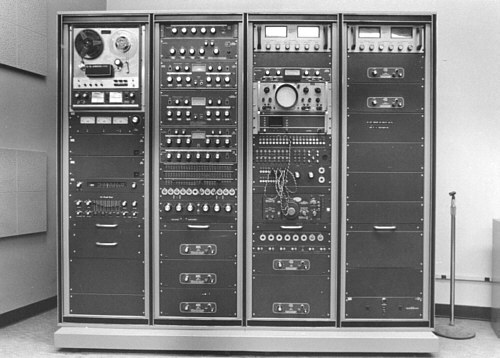

Photo 22

Electronics A-frame in Anaheim - t.u.

Photo 23

Photo 24

Anaheim, test station at the end of the A-frame - t.u.

Photo 25

Electronics lab, Anaheim, late 1970's or early 1980's. The unit on the

bench with the four transistors in the heatsink was a bi-amplifier made for

the A7 - t.u.

Photo 27

Outside the anechoic chamber. What looks like electrical conduit on the

wall behind the racks (that's the wall of the anechoic chamber) is actually

a couple of plane-wave tubes - t.u.

Photo 29

Model 19 home stereo speaker, still made in the early 80's. This one

has the 811B horn and a custom crossover - t.u.

Military applications of Altec products

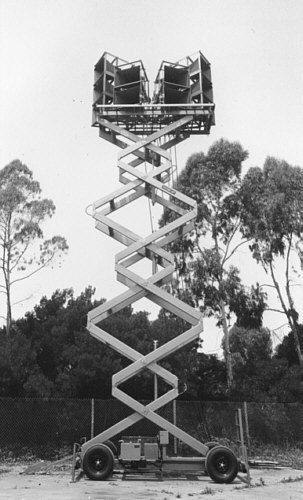

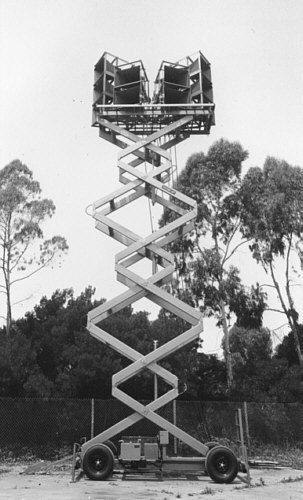

Photo 17

Seven compression drivers, seven re-entrant tone arms, one horn.

Contractors were still begging for this contraption as late as the 1980's - t.u.

Photo 18

9440's, classics, 800 W in a box when everybody else thought that

impossible. Conventional wisdom said that much gain in one box could not be

kept out of oscillation. A guy named Paul Rumbaugh proved them wrong. Made

ca. 1978-1982. It cost $100 in parts and labor to change the light bulb

illuminating ONE of those VU meters - t.u.

Photo 19

Photo 20

Return to page index